Standard pressure gauges generally cope with ambient temperatures down to -40 °C. But what must be the features of a measuring instrument that works perfectly well in polar climates with even lower temperatures? This can be explained using the WIKA PG23LT pressure gauge as an example. This model has been designed specifically for pressure measurement at extremely low ambient temperatures down to -70 °C. It is mainly used in crude oil and natural gas processing; for example, in the local pressure monitoring of pumping stations and pipelines.

Minus 40 °C – this value is often exceeded faster than one thinks. This is demonstrated with a look to Russia. Tables with standard temperature values even indicate more than -60 °C for some regions. For pressure gauges which will be operated in such ambient conditions, two critical points must be observed:

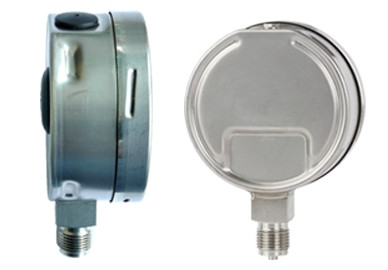

For pressure measurement with extremely low ambient temperatures only available with filled case: WIKA pressure gauge PG23LT.

1. The case filling

A pressure measurement at extremely low ambient temperatures requires a filled pressure gauge design. The liquids used for this protect the instrument from condensation formation within the case resulting from temperature fluctuations. They thus prevent the window from frosting, so that the measured value can still be read safely.

However, the majority of silicone oils used for this purpose begin to solidify at temperatures below -40 °C. The movement then no longer works, or can even freeze. Application-aligned monitoring of the process pressure can no longer be ensured.

For the WIKA PG23LT pressure gauge, a special low-temperature silicone oil has been specified. This oil remains in a state that enables correct pressure measurement and measured value display, even at -70 °C.

The case of the WIKA pressure gauge PG23LT (r.) in comparison to a standard version (l.): It has no elastomers.

2. The elastomers

Elastomers are found in all pressure gauges. They provide a secure sealing between the individual components. In detail, these are the flat gasket at the window, the blow-out device on the rear of the case and the vent valve for pressure compensation.

However, the sealing materials used in standard designs cannot durably withstand very low ambient temperatures. They become brittle over time and lose their sealing properties. This results in the case filling escaping. This, in turn, leads to the formation of condensation and the frosting of the window.

Therefore, in the development of the PG23LT, elastomers have been eliminated in all critical points. The seal between the window and case is made of a special material. It is adapted to extremely low ambient temperatures. The vent valve has a stainless steel cap.

For safety-critical applications, the pressure gauge is also available in a version with a solid baffle wall and blow-out back with a safety category “S3” in accordance with EN 837-1. In this case, the O-ring seal on the blow-out back is also made of a special material that seals durably and reliably, even at extremely low temperatures.

Note

Further information on the PG23LT low-temperature pressure gauge can be found on the WIKA website.